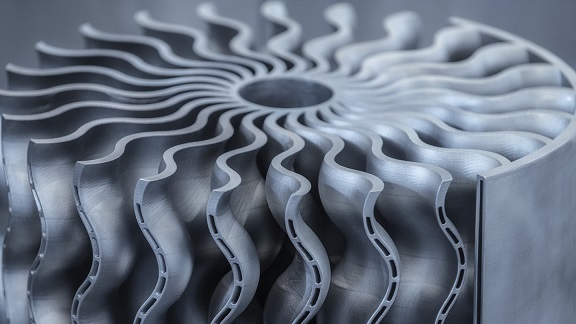

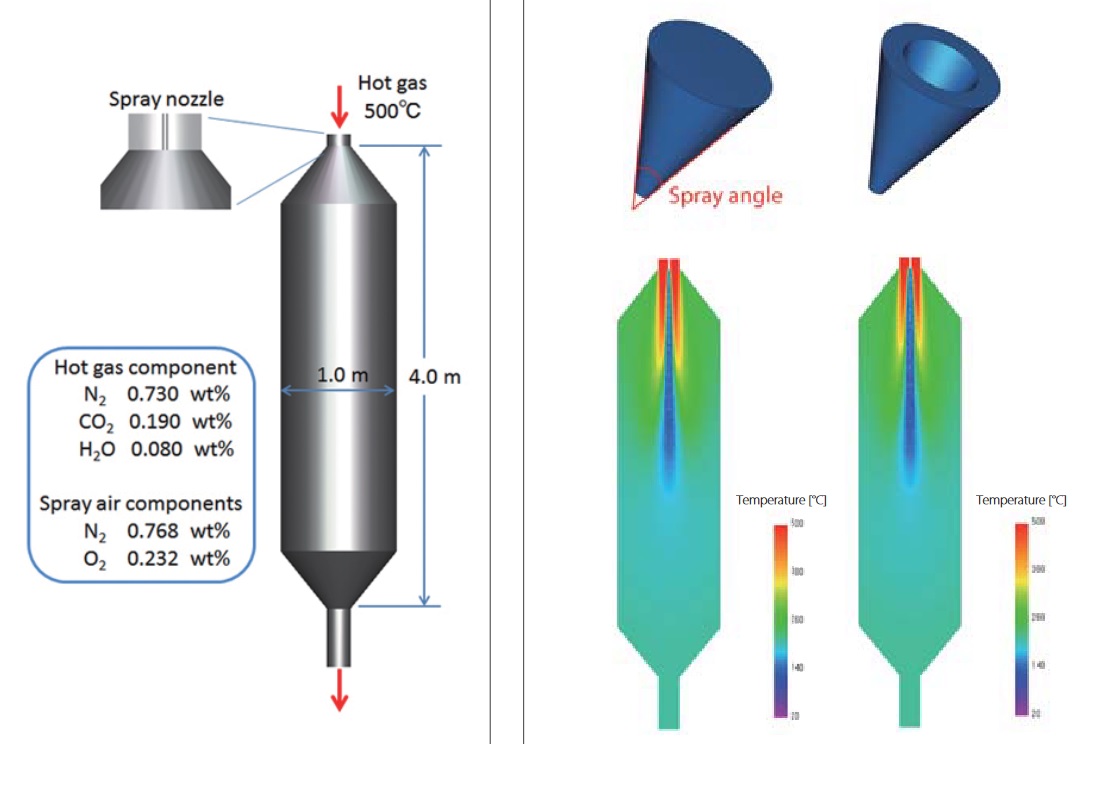

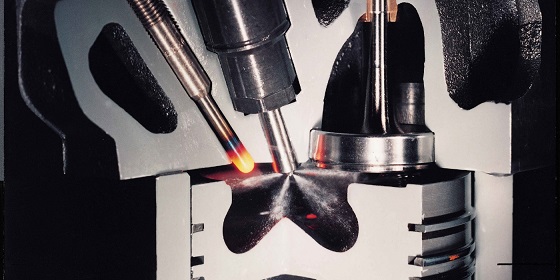

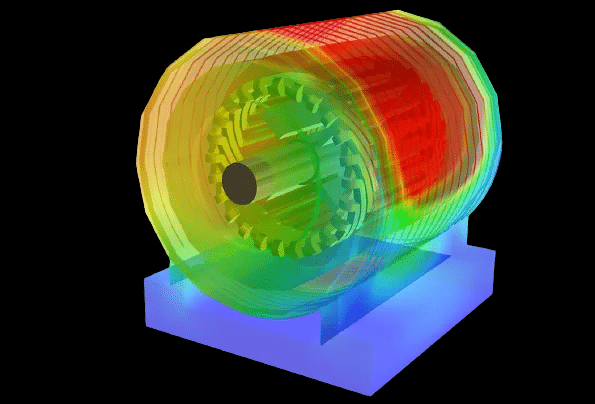

Heat Transfer Simulations for Turbomachinery

explore

Most machines, such as high-heat turbines (gas and steam), boilers, and combustors for example, require strict control of thermal stresses and expansions. Due to the …

Discover More